Technical Specification

Lorem ipsum dolor sit amet consectetur

Jaw Crusher

Technical Specification

| Jaw Crusher Size | Recommended Feed Size | Capacity In Tons Per Hour With Jaw Setting Of | R.P.M. | Drive H.P. | Approx. Wgt. In Kgs. |

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MM | Inches | MM | MM | 13 | 20 | 25 | 31 | 37 | 50 | 62 | 75 | 87 | 100 | 125 | 150 | 175 | 200 | |||

| Inches | 1/2" | 3/4" | 1" | 1¼" | 1½" | 2" | 2½" | 3" | 3½" | 4" | 5" | 6" | 7" | 8" | ||||||

| 300 x 175 | 12" x 7" | 137.5 | 5½" | 6 | 7 | 8 | 10 | 13 | 18 | 25 | 365/400 | 20 | 1100 | |||||||

| 300 x 225 | 12" x 9" | 175 | 7" | 7 | 9 | 10 | 12 | 15 | 20 | 28 | 365/400 | 20 | 1450 | |||||||

| 400 x 225 | 16" x 9" | 175 | 7" | 8 | 11 | 13 | 15 | 16 | 22 | 31 | 365/400 | 25 | 2620 | |||||||

| 500 x 300 | 20" x 12" | 250 | 10" | 13 | 16 | 19 | 22 | 30 | 38 | 45 | 350/380 | 30 | 4750 | |||||||

| 750 x 225 | 30" x 9" | 250 | 10" | 22 | 24 | 28 | 30 | 32 | 35 | 39 | 320/350 | 30/40 | 6900 | |||||||

| 750 x 375 | 30" x 15" | 300 | 12" | 35 | 44 | 58 | 64 | 71 | 89 | 320/350 | 40 | 8500 | ||||||||

| 900 x 200 | 36" x 8" | 150 | 6" | 35 | 44 | 52 | 62 | 85 | 96 | 320/350 | 50 | 9400 | ||||||||

| 900 x 500 | 36" x 20" | 400 | 16" | 62 | 73 | 80 | 102 | 120 | 142 | 320/350 | 60 | 11200 | ||||||||

| 900 x 600 | 36" x 24" | 500 | 20" | 84 | 111 | 125 | 138 | 174 | 250/280 | 75/100 | 18500 | |||||||||

| 1050 x 750 | 42" x 30" | 600 | 24" | 142 | 178 | 200 | 200 | 223 | 250/280 | 100/125 | 23000 | |||||||||

| 1200 x 225 | 48" x 9" | 175 | 7" | 19 | 29 | 38 | 48 | 57 | 76 | 39 | 320/350 | 75 | 14000 | |||||||

| 1200 x 900 | 48" x 36" | 750 | 30" | 192 | 230 | 269 | 307 | 220/250 | 75/100 | 27000 | ||||||||||

- Jaw setting to the left of red line are not recommended if any one desires to keep a close setting than recommended. It is must to maintain the correct feed size in the ratio 8:1

- Capacity are based on crushing average hard rock with bulk density of 100 lbs/cft or 1600 kg per cubic meter & tended as guide only. Capacity can very dependent on the rock characteristics, feed size & feeding arrangements. The actual production capacity is calculated on the basis of 70% - 80% machine efficiency and required output size is calculated on the basis of 60% - 65% of the actual output which can be increased.

- For achieving cubical product from the crusher, usage of serrated jaw plates are recommended. While using serrated jaw plates, capacity figure may get reduced.

-

NOTICE:

- The above chart gives an indication of the capacities of our Jaw Crusher based above capacities are approximate and subject to variations.

- We reserve the rights to make any alterations and or modifications which we consider on improvement.

- Do not use these dimensions for actual installation work.

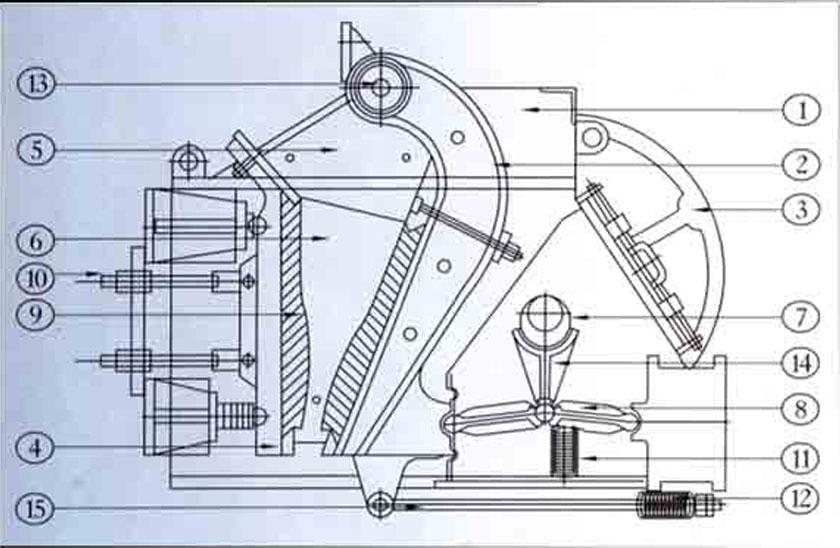

- Body

- Swing Jaw

- Fly Wheel

- Stationary Jaw

- Upper side Plate

- Lower Side Plate

- Eccentric Shaft

- Toggle Plate

- Jaw Plate

- St. Jaw Holding Stud

- Toggle Spring

- Foot Rod Spring

- Hing Pin

- Pitman

- Foot Rod

BODY

- Heavy steel plates welded construction with excess strength and expertly welded. The side walls are stiffened by strength longitudinal and transverse ribs.

SWING JAW

- It is designed and balanced to avoid power losses through lifting on crushing stock for maximum crusing.

JAW PLATES

- Both the fixed swing jaw plates are casted in the best quality of manganese steel. Wide range of plates with different configurations.

ECCENTRIC SHAFT

- It is accurately machined. it made of alloy steel mounted in self aligned spherical roller bearings of ample capacity for smooth running with enables load to be observed by solid frame.

FLY WHEEL

- It is graded cast iron which act as flywheel come driving pully which the law inertia of mechanism.

TOGGLE

- Double toggles give better distribution of load well designed compression springs provide cushioning to the toggle mechanism eliminate knocks and reduce the resultant wear.

HING PIN

- It is on the central line of the crushing chamber for direct crushing without rubbing. It made of alloy steel.

LUBRICATION

- Continuous lubrication is provided with positive rotary pumps to toggles, pitman mechanism rotary pump is coupled direct on eccentric shaft.

ADJUSTMENT

- Setting the jaw opening is quick and easy with all adjustments carried out on the stationary jaw correct crushing geometry is not disturbed at all.

PITMAN

- Pitman is always in compression and as such it is very light in design than any other conventional pitman.

APPLICATION

- Hard Rock, River Gravel, Black Trap Rock, Granite, Lime Stone, Coal, Coke, Iron Ore, Bauxite, Manganese Ore, Hematite Ores, etc.

SIZE

- Apart from sizes of PRIYA JAW CRUSHER indicated, other size can also be quoted to suit special requirements if any.

POWER

- House power required is based on use of electric motors in normal condition. Petrol or Diesel Engine should be of approx. 20 to 25% higher capacity than electric motors, and also subject to losses due to attitude.

CAPACITIES

- Capacities given are neither minimum nor maximum due to wide variation in the crushing characteristic of different rocks and ores. The output rating are based on continuous feeding and second feed does not exceed 80% of crusher opening size. Output given is, based on recommended maximum feed size.

LUBRICATION

- Use ESSO or Castrol anti friction grease or oil in this crusher machine for Roller Bearing Protection.

OUTPUT

- The output in tons indicated is based on average hard dry quartz or similar rock weighting at least 100 lbs. per cubic ft. when crushed, and on continuous feed of grade sizes with fines removed, it is subject to variation depending on working conditions. Special granulator jaw plates are to be fitted to work for 16" x 9" crusher for the product size of 3/4" and under.